Custom casting

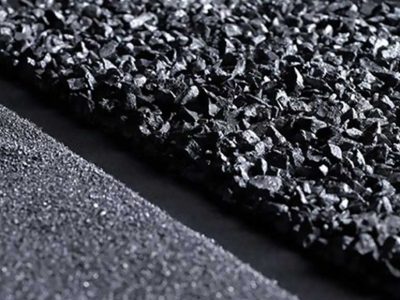

In general, casting is the science and technique of forming alloys of different metals, which is done by melting materials and placing molten material in refractory molds, and the process of cooling and freezing materials afterwards. Machines, devices and etc., can be produced using this process.

Designing and production

On this era, casting is required in various fields and has many applications in industry, art, technology and etc. The casting process is one of the oldest sciences and is 7,000 years old. Now, with the advancement of technology and the creation of different methods, casting process leads to the best results ever. The desired part must be designed by the designers and then enter the process of production.

The most important stage in casting customized cast iron parts is manufacturing the mold, which is divided into two types of disposable and permanent ones.

Casting in disposable molds:

These molds, as the name implies, disappear after a single casting process. Sand molds are one of the most widely used molds in this category.

Casting in permanent molds:

These molds do not have the property of expansion, they are made of metal and as the name suggests, they are not damaged after casting and removing the product from the mold, and can be reused many times

Casting methods depend on equipment and technology and various factors.

- Design and production of custom parts is done in different ways:

- Types of casting molds:

- Casting with consumable molds

- Precision Casting

- Shell casting

- Performing the casting process.

- Quality control of the final product

- If needed, cutting and machining processes are done.

- Putting in the furnace if heat treatment is required.

- Final control of the manufactured parts and performing various QC tests.

- Dispatching the products to the customers.

All casting methods have special applications and according to the required part, the number of parts, the desired quality, the required material, the dimensions of the part and the material of the mold, etc., each of these methods is used.

Sahand Azarin Company offers the best services to its customers by having the highest quality equipment and the latest technologies in the foundry industry. You can contact our professional experts and get advice through the contact us page..

faq

- Production of various and complex parts in diverse numbers and dimensions

- Capability of manufacturing very large and heavy parts

- Ability to manufacture internal and external parts of the product

- Suitable for mass production and automated production process in some casting methods

- High risk of the process due to working with molten materials

- Creating environmental problems and high energy consumption

- Ferrous and non-ferrous metals can be used in the casting process. Ferrous metals such as iron and cast iron, non-ferrous metals such as bronze, brass, aluminum alloys, magnesium, zinc and…. .